Instead of using traditional machines to shape a part, product, or tool, we can help you speed up the process with our precision CNC machining services. With technological advancement, CNC machines are the best option for subtractive manufacturing.

You can send us your requirement, and we will get them done for you at our workshop. We are only serving in Canada. Fill out the form below to get a quote today.

Our CNC Machine Shop

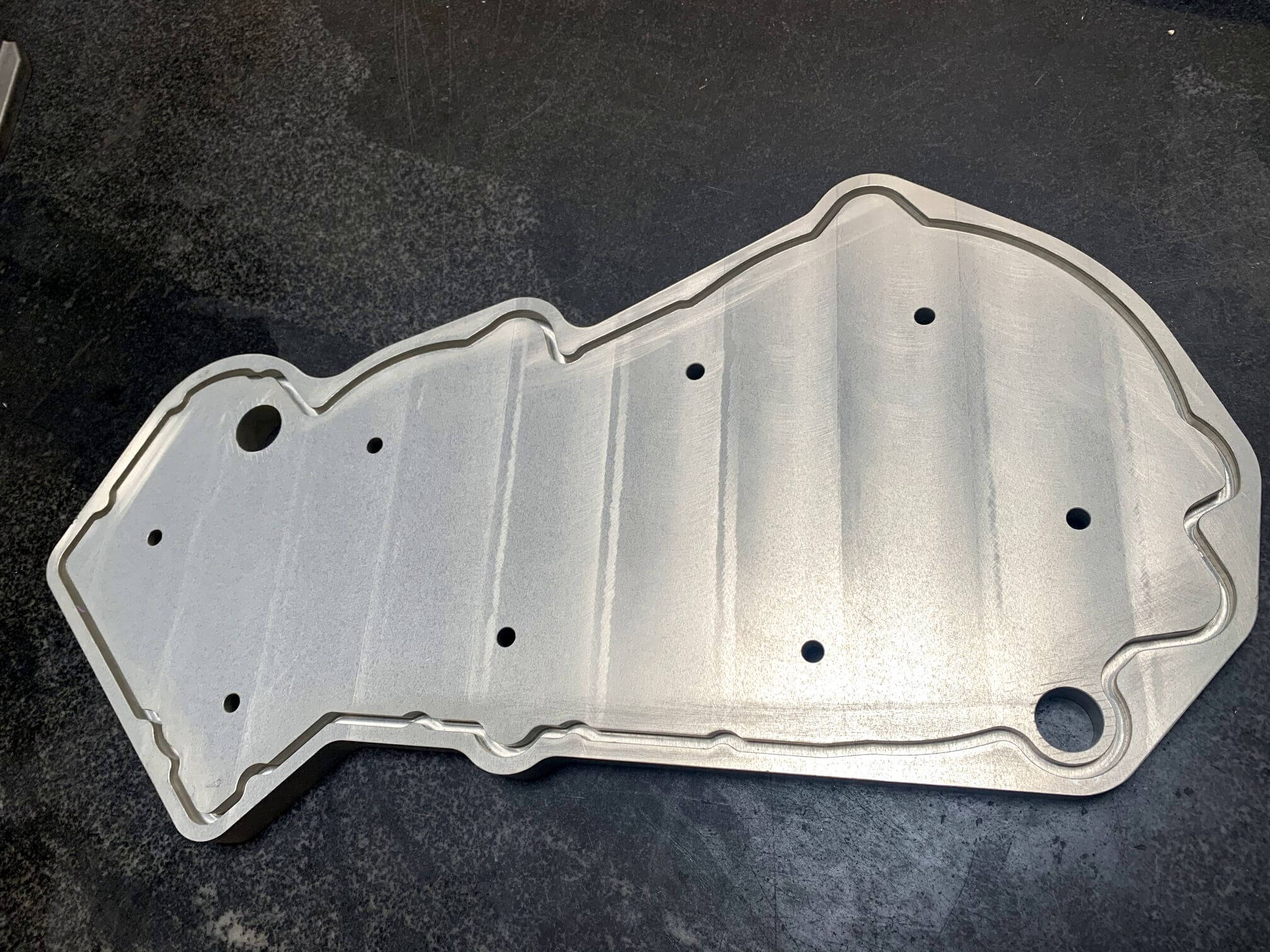

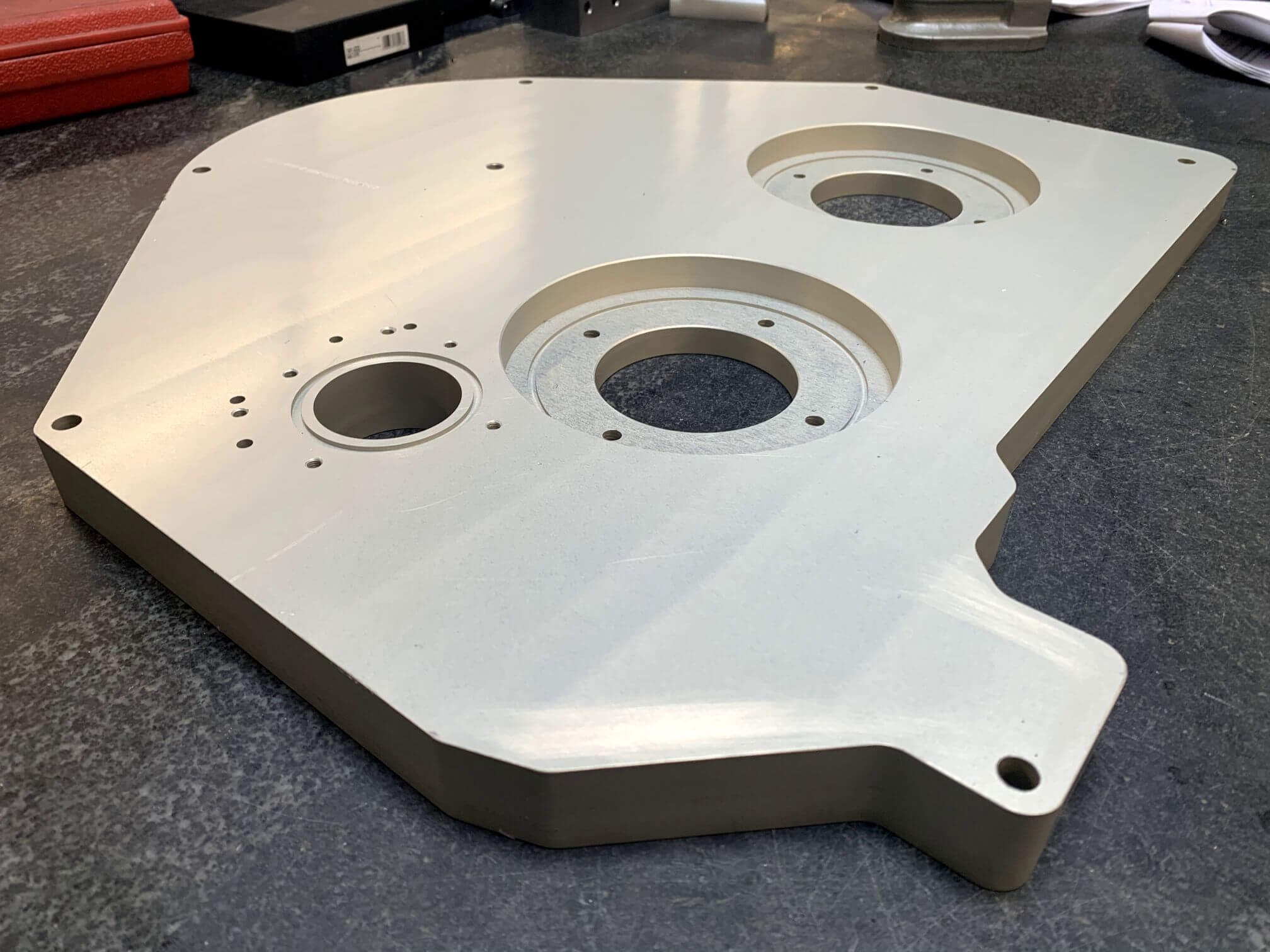

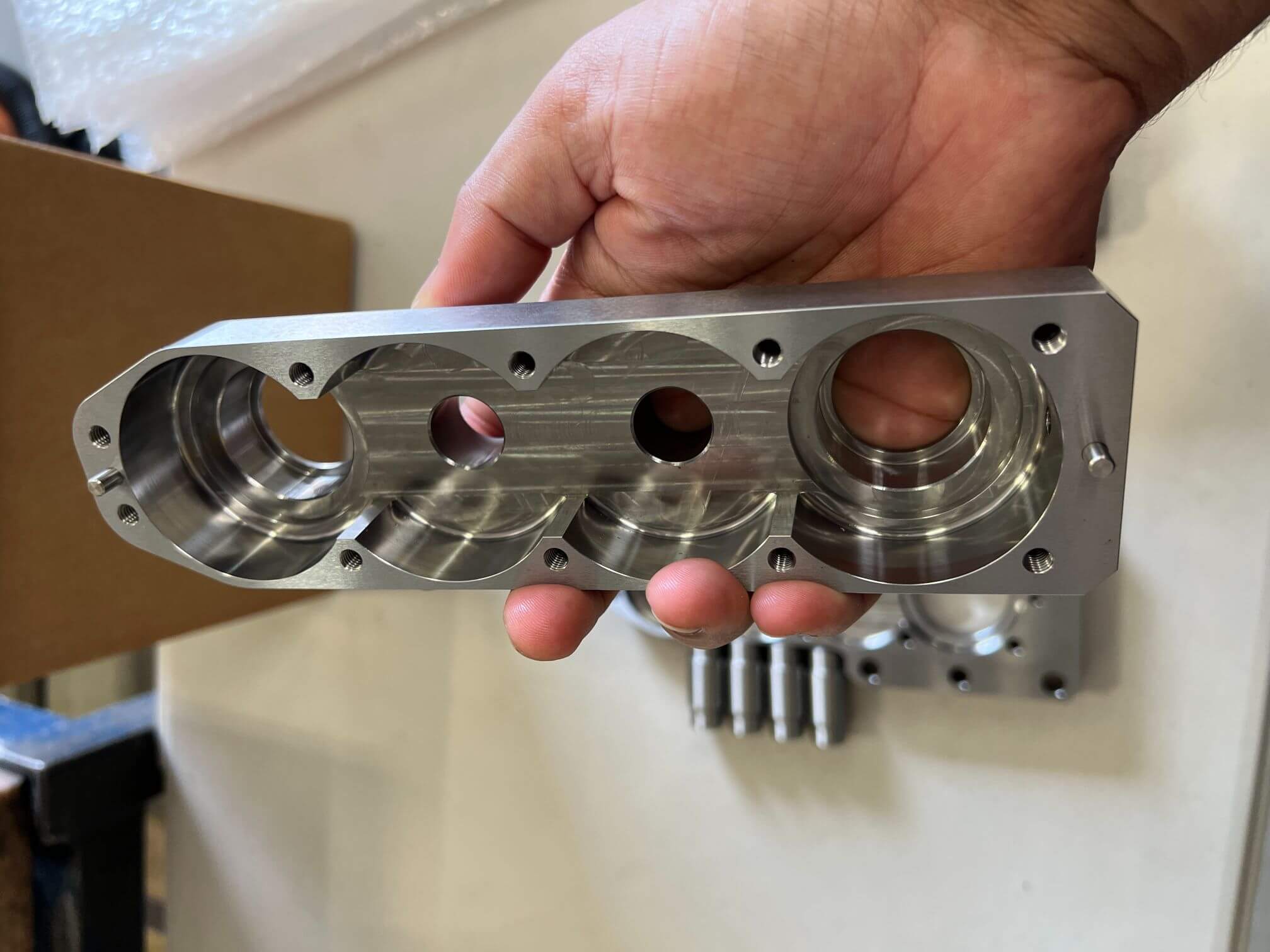

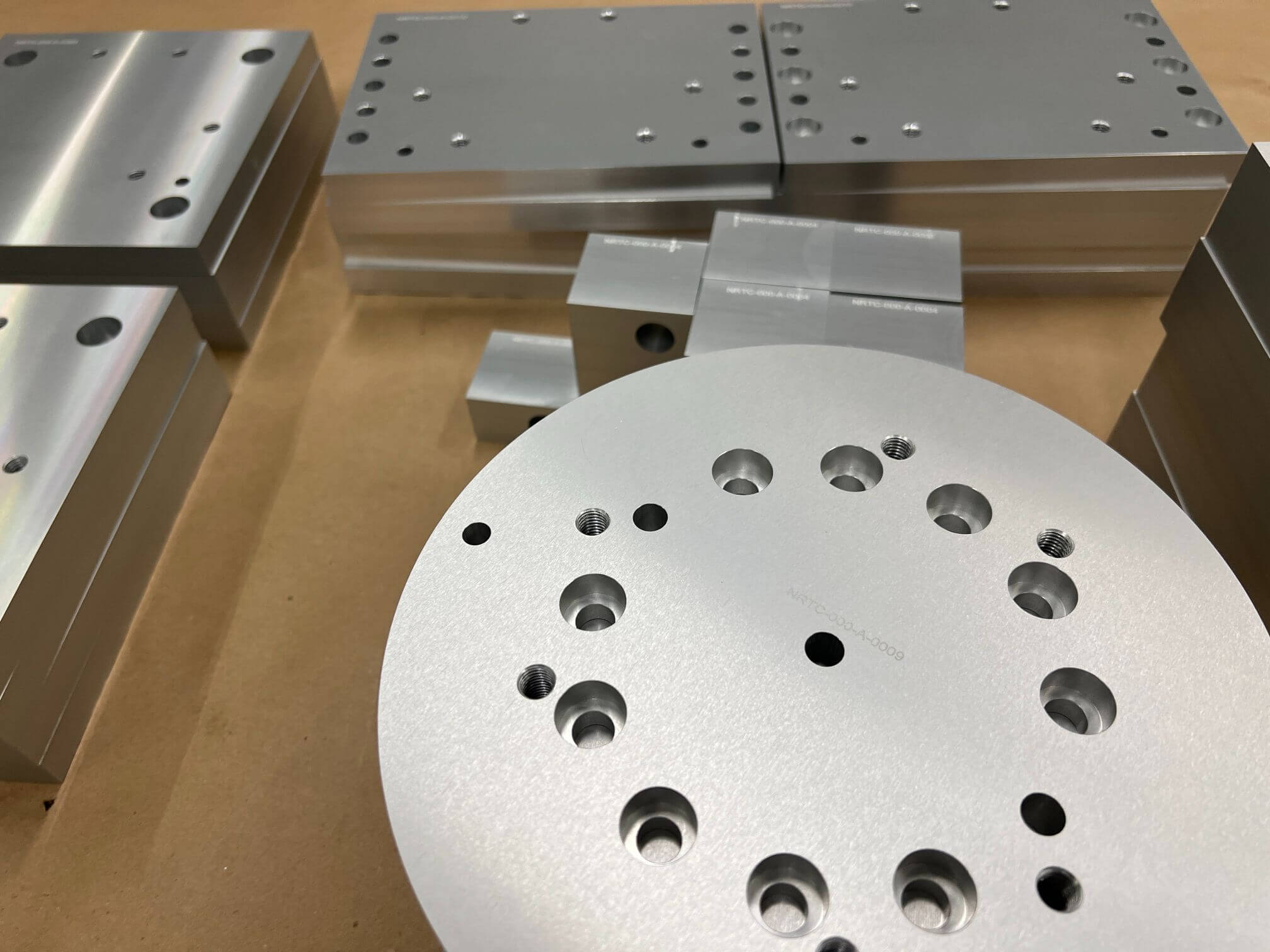

As mentioned in the above section, subtractive manufacturing includes material removal processes such as turning, drilling, milling, cutting, grinding, etc. Our CNC machine shop has the setup ready to kickstart your work. You can see our portfolio in the “Our Work” section.

To get started, fill out the form below, along with the CAD design to get started.